Difference between revisions of "October 05, 2022 FCAL Insert Installation Meeting"

From GlueXWiki

| Line 50: | Line 50: | ||

** Can we use scaffolding on the temporary platform? | ** Can we use scaffolding on the temporary platform? | ||

* Discussed insulation vacuum vs. standard - standard foam board ok since delta T is small | * Discussed insulation vacuum vs. standard - standard foam board ok since delta T is small | ||

| + | |||

| + | * Discussed monitoring panel design for the crystals in a separate meeting | ||

| + | ** Arshak showed his testing and baseline design | ||

| + | *** Optical fibers coming in on all 4 outer edges (120 fibers for now) | ||

| + | *** 1/2" acrylic sheet in 2 pieces | ||

| + | ** Discussed how to route fibers | ||

| + | *** through holes in FCAL2 step frames - bushings needed | ||

| + | *** route over glass module monitoring panel | ||

| + | *** maybe have fiber connections at upstream surface and install with rohacell backbone and tungsten absorber as an assembly | ||

| + | *** is there 90° connectors for fibers or generous bend radius needed? | ||

| + | ** Discussed supporting outer edges of panel to rohacell for stability | ||

== Action Items == | == Action Items == | ||

| Line 56: | Line 67: | ||

* Update baseline schedule with additional items discussed - Scot | * Update baseline schedule with additional items discussed - Scot | ||

* Come up with a written cable mapping plan - Sasha | * Come up with a written cable mapping plan - Sasha | ||

| + | * Update 3D model for patch panels - Stephanie | ||

| + | * Develop cable routing plan under platform - Tim/Scot/Stephanie | ||

| + | * Check on use of scaffolding on the platform - Scot | ||

* | * | ||

Revision as of 14:48, 11 October 2022

Meeting Time and Place

Wednesday October 05, 2022 10am At Jefferson Lab, Hall D Counting House and on Teams

Agenda

- Minutes from last meeting https://halldweb.jlab.org/wiki/index.php/October_07,_2022_FCAL_Insert_Installation_Meeting

- Discuss Lead Glass and crystal module removal/install] - Sasha

- Use of platform upstream of detector - Stephanie/Tim

- Discuss cable mapping - Sasha

- Existing cables

- New Cables

- Cable quotes 0 Chris S.

- Existing structure can support 2500lbs

- Monitoring system discussion directly after

- Assembly in ESB

- Media:FCAL2_strawman_schedule.pdf

Minutes

- Discussed lead glass module removal/install

- Lead glass blocks will be installed as they are now with alternating SS vertical and then horizontal

- Refurbishing existing module bases is about 1 hour for Malte and Mark, but Chris S. also has to do very delicate work also

- Students may help base repairs but ES&H input would be needed

- Since there is no time to design, test and fabricate new bases for the existing modules, we will stick to repairing existing bases

- The worst bases should be removed in March before taking apart the detector so the repairs can be started

- More detail needed on existing module refurbish plan

- Mark D. has database for existing module and will come up with an initial plan for sorting

- Existing cables that may be used need to be relabeled and put in database

- Eugene expressed that we should work with the mini FCAL to develop the removal/refurbish plan

- Cable discussions

- Fernando expressed that in the tight area, LV cables should not be ribbon cables - 1 cable for each base should be used

- Revisited signal cable plan to come from downstream wall through patch panel - Mark D. not at previous meeting - seems ok

- Six patch panels in all for all new cables - need to start designing this for dark room and reinforcements needed

- Existing I-beam over dark room should handle additional cable weight

- Need to look at cable routing under platform and come up with a layout

- Sasha needs to come up with a cable mapping plan to help reach decisions on using existing cables or removing all

- Chris S. will ship out 1200 signal cables to get terminated

- Chris S. to get quote on additional 400 signal cables

- Chris already request quote for 1600 new thin (RG174) signal cables to go from patch panel to detectors

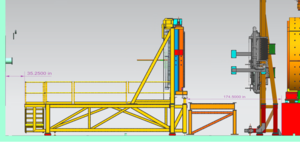

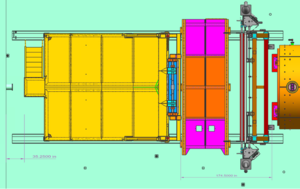

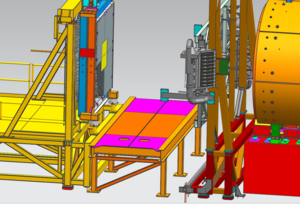

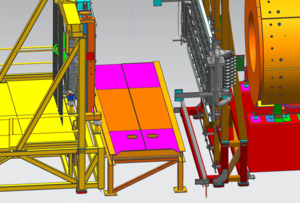

- Looked at using the existing BCAL install platform on the upstream side of the FCAL.

- We should probably use this regardless of decision to remove cables from crates

- Can we use scaffolding on the temporary platform?

- Discussed insulation vacuum vs. standard - standard foam board ok since delta T is small

- Discussed monitoring panel design for the crystals in a separate meeting

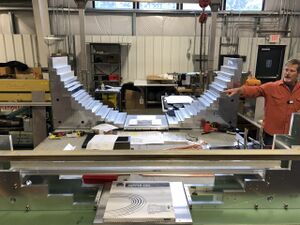

- Arshak showed his testing and baseline design

- Optical fibers coming in on all 4 outer edges (120 fibers for now)

- 1/2" acrylic sheet in 2 pieces

- Discussed how to route fibers

- through holes in FCAL2 step frames - bushings needed

- route over glass module monitoring panel

- maybe have fiber connections at upstream surface and install with rohacell backbone and tungsten absorber as an assembly

- is there 90° connectors for fibers or generous bend radius needed?

- Discussed supporting outer edges of panel to rohacell for stability

- Arshak showed his testing and baseline design

Action Items

- Send out 1200 signal cables to get terminated - Chris S.

- Start looking at how to use the existing database for lead glass handling - Mark D

- Update baseline schedule with additional items discussed - Scot

- Come up with a written cable mapping plan - Sasha

- Update 3D model for patch panels - Stephanie

- Develop cable routing plan under platform - Tim/Scot/Stephanie

- Check on use of scaffolding on the platform - Scot