Difference between revisions of "November 02, 2022 FCAL Insert Installation Meeting"

From GlueXWiki

(→Agenda) |

(→Minutes) |

||

| Line 33: | Line 33: | ||

== Minutes == | == Minutes == | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Action Items == | == Action Items == | ||

Revision as of 07:26, 2 November 2022

Meeting Time and Place

Wednesday November 02, 2022 10am At Jefferson Lab, Hall D Counting House and on Teams

Agenda

- Minutes from last meeting https://halldweb.jlab.org/wiki/index.php/October_19,_2022_FCAL_Insert_Installation_Meeting

- Discuss Lead Glass and crystal module removal/install [1] - Sasha

- Initial testing of modules before removal - Mark D.

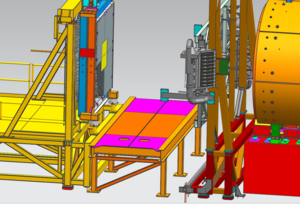

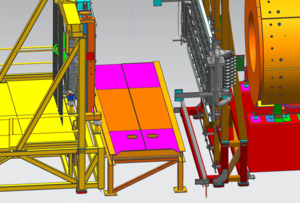

- Revisited removal of darkroom -

- All cables need to be removed from darkroom to be able to install new detector

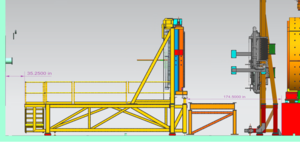

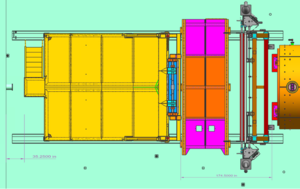

- Maybe able to crane frame off platform partially assemble

- Rework for patch panels

- Cable discussion fruitful

- Option D to move cables from inner 400 cables to adjacent crate

- Remove 2 crates and move to new racks

- Abandon 200 cables

- Patch panels worked out, 2 HV and 2 LV north and south side, 1 signal feedthrough plate downstream wall

- HV and LV cable length = 20 ft

- Signal cable length = 16 ft

- Cable trays for Signal all going N-S under platform

- HV and LV cables al come from underneath also

- Monitoring system discussion

- Assembly in ESB

- Media:FCAL2_strawman_schedule.pdf

Minutes

Action Items

- Set up separate meeting for Cable mapping and requirements - Tim

- Continue to work on unstacking, categorizing and repair plan - Sasha, Mark D.?

- Develop layout for patch panels - Stephanie/Chris S

- Continue to develop current monitoring design - Stephanie/Arshak

- Work on cable tray layout - Tim/Stephanie

- Provide lengths for HV and LV cables inside dark room - Tim/Stephanie