Difference between revisions of "November 02, 2022 FCAL Insert Installation Meeting"

From GlueXWiki

(→Agenda) |

(→Minutes) |

||

| (12 intermediate revisions by 2 users not shown) | |||

| Line 7: | Line 7: | ||

* Minutes from last meeting https://halldweb.jlab.org/wiki/index.php/October_19,_2022_FCAL_Insert_Installation_Meeting | * Minutes from last meeting https://halldweb.jlab.org/wiki/index.php/October_19,_2022_FCAL_Insert_Installation_Meeting | ||

* Discuss Lead Glass and crystal module removal/install [https://halldweb.jlab.org/wiki/index.php/FCAL_Installation] - Sasha | * Discuss Lead Glass and crystal module removal/install [https://halldweb.jlab.org/wiki/index.php/FCAL_Installation] - Sasha | ||

| + | * Manpower and task division [https://halldweb.jlab.org/wiki/index.php/FCAL_Installation] - Sasha | ||

* Initial testing of modules before removal - Mark D. | * Initial testing of modules before removal - Mark D. | ||

* Revisited removal of darkroom - | * Revisited removal of darkroom - | ||

| Line 19: | Line 20: | ||

** HV and LV cable length = 20 ft | ** HV and LV cable length = 20 ft | ||

** Signal cable length = 16 ft | ** Signal cable length = 16 ft | ||

| + | ** Cable trays for Signal all going N-S under platform | ||

| + | ** HV and LV cables al come from underneath also | ||

* Monitoring system discussion | * Monitoring system discussion | ||

* Assembly in ESB | * Assembly in ESB | ||

| Line 31: | Line 34: | ||

== Minutes == | == Minutes == | ||

| − | * Reviewed minutes from | + | * Reviewed minutes from last meeting |

| − | * Sasha | + | * Looked at Sasha's installation wiki page |

| − | ** | + | ** Showed different possible damage to wrapping of existing lead glass modules |

| − | ** | + | ** Is aluminum being stuck to module surface a performance issue (light yield)? |

| − | ** | + | *** Really no way to test now |

| − | * | + | *** Need to decide threshold for re-wrapping |

| − | ** Need to | + | ** Some inspection/labelling needed prior to unstacking of blocks |

| − | ** | + | ** Sasha proposed that him and Arshak inspect each module after removal to decide on action to be taken - |

| − | ** | + | ** Mark and Malte need to be in loop for base and pmt changes |

| − | ** | + | *** Possibly test light yield on first 100 |

| − | ** | + | ** Malte asked who unstacked the original modules from BNL and what were the issues |

| − | * | + | ** Looks like we will have about 500 good PMT spares |

| − | * | + | ** Sasha presented manpower requirements |

| − | * | + | *** would need 2 students for 30 weeks to re-wrap all old modules |

| − | ** | + | *** Total 11 students for 3 months will be needed for project (Eugene to check budgets) |

| − | ** | + | *** JLAB folks responsible for unstacking modules - Hall D Techs/DSG? |

| − | ** | + | *** Sasha/Arshak would train students to do module refurb |

| − | * | + | *** Students would label and bundle cables |

| − | + | *** JLAB tech staff handle structure, darkroom, cable trays, racks | |

| − | + | *** JLAB electronics group handle crate installation and cabling possibly with help from DSG | |

| − | * | + | *** Students would handle moving existing cables to adjacent crates on north and south racks |

| − | * | + | *** Need to get a final list of universities supplying students |

| − | + | *** Maybe best to downgrade the hall from RAD worker 1 to Gert only | |

| − | * | + | ** Sasha mentioned the need to re-strap some existing 25 micron brass strap crystal modules |

| − | * | + | ** Need to start developing procedures for all aspects of the project |

| − | * | + | ** Need to define workstations needed - add to Sasha's table and develop a layout |

| − | * | + | * Need to have electric power added to south side of FCAL platform |

| − | * | + | * Need to update strawman schedule with more detail including resources |

| − | * | + | * Lead glass acrylic sheet same design as original - need to remake panes for new geometry |

| − | ** | + | |

| − | ** | + | |

| − | * | + | |

| − | ** | + | |

| − | * | + | |

| − | * | + | |

| − | ** Need to get | + | |

| − | ** | + | |

| − | ** Sasha | + | |

| − | ** | + | |

| − | + | ||

| − | ** | + | |

| − | * | + | |

| − | * | + | |

| − | * | + | |

== Action Items == | == Action Items == | ||

| − | * | + | * Develop required work stations needed and add to table - Sasha |

| − | + | * Develop hall layout based on work stations - Tim/Stephanie | |

| − | * Develop layout | + | * Update Gant chart with more detail and resources - Scot/Tim |

| − | * | + | * Check to see if hall can be downgraded to a Radiologically Controlled area - Tim |

| − | * | + | * Start developing procedures - Sasha - Tim |

| − | * | + | * Determine what universities/students will be available - Sasha |

| + | * Have electricians look at bringing power to new racks on south side - Tim | ||

| + | * Determine if we have budget for students - Eugene | ||

| + | * Design patch panels - Chris S./Stephanie | ||

Latest revision as of 13:23, 3 November 2022

Meeting Time and Place

Wednesday November 02, 2022 10am At Jefferson Lab, Hall D Counting House and on Teams

Agenda

- Minutes from last meeting https://halldweb.jlab.org/wiki/index.php/October_19,_2022_FCAL_Insert_Installation_Meeting

- Discuss Lead Glass and crystal module removal/install [1] - Sasha

- Manpower and task division [2] - Sasha

- Initial testing of modules before removal - Mark D.

- Revisited removal of darkroom -

- All cables need to be removed from darkroom to be able to install new detector

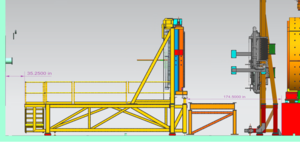

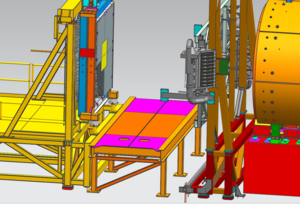

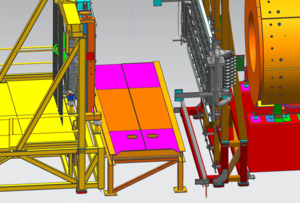

- Maybe able to crane frame off platform partially assemble

- Rework for patch panels

- Cable discussion fruitful

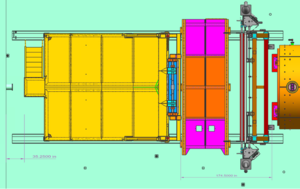

- Option D to move cables from inner 400 cables to adjacent crate

- Remove 2 crates and move to new racks

- Abandon 200 cables

- Patch panels worked out, 2 HV and 2 LV north and south side, 1 signal feedthrough plate downstream wall

- HV and LV cable length = 20 ft

- Signal cable length = 16 ft

- Cable trays for Signal all going N-S under platform

- HV and LV cables al come from underneath also

- Monitoring system discussion

- Assembly in ESB

- Media:FCAL2_strawman_schedule.pdf

Minutes

- Reviewed minutes from last meeting

- Looked at Sasha's installation wiki page

- Showed different possible damage to wrapping of existing lead glass modules

- Is aluminum being stuck to module surface a performance issue (light yield)?

- Really no way to test now

- Need to decide threshold for re-wrapping

- Some inspection/labelling needed prior to unstacking of blocks

- Sasha proposed that him and Arshak inspect each module after removal to decide on action to be taken -

- Mark and Malte need to be in loop for base and pmt changes

- Possibly test light yield on first 100

- Malte asked who unstacked the original modules from BNL and what were the issues

- Looks like we will have about 500 good PMT spares

- Sasha presented manpower requirements

- would need 2 students for 30 weeks to re-wrap all old modules

- Total 11 students for 3 months will be needed for project (Eugene to check budgets)

- JLAB folks responsible for unstacking modules - Hall D Techs/DSG?

- Sasha/Arshak would train students to do module refurb

- Students would label and bundle cables

- JLAB tech staff handle structure, darkroom, cable trays, racks

- JLAB electronics group handle crate installation and cabling possibly with help from DSG

- Students would handle moving existing cables to adjacent crates on north and south racks

- Need to get a final list of universities supplying students

- Maybe best to downgrade the hall from RAD worker 1 to Gert only

- Sasha mentioned the need to re-strap some existing 25 micron brass strap crystal modules

- Need to start developing procedures for all aspects of the project

- Need to define workstations needed - add to Sasha's table and develop a layout

- Need to have electric power added to south side of FCAL platform

- Need to update strawman schedule with more detail including resources

- Lead glass acrylic sheet same design as original - need to remake panes for new geometry

Action Items

- Develop required work stations needed and add to table - Sasha

- Develop hall layout based on work stations - Tim/Stephanie

- Update Gant chart with more detail and resources - Scot/Tim

- Check to see if hall can be downgraded to a Radiologically Controlled area - Tim

- Start developing procedures - Sasha - Tim

- Determine what universities/students will be available - Sasha

- Have electricians look at bringing power to new racks on south side - Tim

- Determine if we have budget for students - Eugene

- Design patch panels - Chris S./Stephanie