Difference between revisions of "ANSYS simulations"

(→Summary of field simulations for the 30D72 magnet from BNL) |

|||

| Line 8: | Line 8: | ||

| − | [[Image:30D72_MaxField. | + | [[Image:30D72_MaxField.jpg |350px]] |

For 2T each 106 turns per coil was required. The assembly drawings indicate that there are 4 layers of | For 2T each 106 turns per coil was required. The assembly drawings indicate that there are 4 layers of | ||

| − | conductor per magnet half. For each magnet half there are 2 separate coil packages each with 2 layers of conductors. 106 turns corresponds to about 26 turns per layer. There is no size copper which matches well to | + | conductor per magnet half. For each magnet half there are 2 separate coil packages each with 2 layers of conductors. 106 turns corresponds to about 26 turns per layer. There is no size copper which matches well to the outside dimensions and 26 conductors per layer. 3/4" conductor would correspond to 16 conductors per layer. Clearly more details of the coil are needed. For now it should be assumed the actual current could be 60% higher then what is input to the siulation. |

Revision as of 13:15, 3 February 2009

Summary of field simulations for the 30D72 magnet from BNL

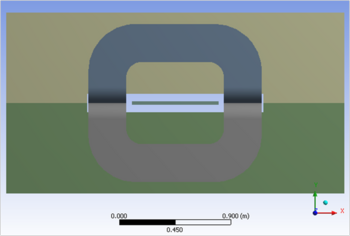

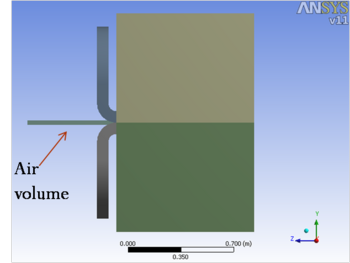

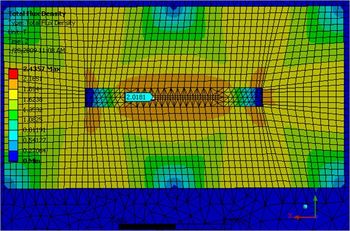

The BNL 30D72 magnet has been modeled in Ideas based on the original drawings of the iron cores. The model was imported into ANSYS as a step fiel and used as the basis of a magnetostatic simulation. The side view o the right only shows the left half of the magnet. In the simulation a symmetry plane is inserted in the z=0 plane and only half the magent is calculated.

Detailed drawings of the coils were not available so approximatate values needed to be determined from the known specifications of the magnet. The specification states that the magnet will have a maximum field of 2T at an operating current of 2500 A. The number of turns was adjusted to match this. It was assumed that the magnet is made from 1006 steel.

For 2T each 106 turns per coil was required. The assembly drawings indicate that there are 4 layers of conductor per magnet half. For each magnet half there are 2 separate coil packages each with 2 layers of conductors. 106 turns corresponds to about 26 turns per layer. There is no size copper which matches well to the outside dimensions and 26 conductors per layer. 3/4" conductor would correspond to 16 conductors per layer. Clearly more details of the coil are needed. For now it should be assumed the actual current could be 60% higher then what is input to the siulation.