November 02, 2022 FCAL Insert Installation Meeting

From GlueXWiki

Meeting Time and Place

Wednesday November 02, 2022 10am At Jefferson Lab, Hall D Counting House and on Teams

Agenda

- Minutes from last meeting https://halldweb.jlab.org/wiki/index.php/October_19,_2022_FCAL_Insert_Installation_Meeting

- Discuss Lead Glass and crystal module removal/install [1] - Sasha

- Initial testing of modules before removal - Mark D.

- Revisited removal of darkroom -

- All cables need to be removed from darkroom to be able to install new detector

- Maybe able to crane frame off platform partially assemble

- Rework for patch panels

- Cable discussion fruitful

- Option D to move cables from inner 400 cables to adjacent crate

- Remove 2 crates and move to new racks

- Abandon 200 cables

- Patch panels worked out, 2 HV and 2 LV north and south side, 1 signal feedthrough plate downstream wall

- HV and LV cable length = 20 ft

- Signal cable length = 16 ft

- Monitoring system discussion

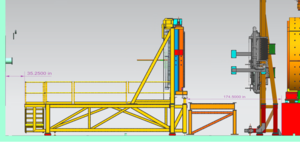

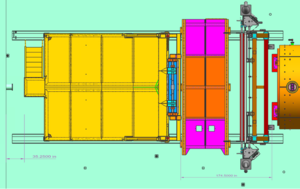

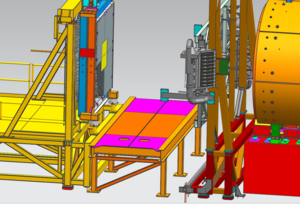

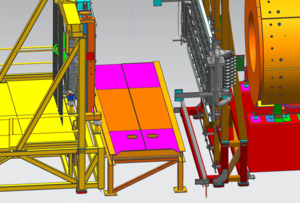

- Assembly in ESB

- Media:FCAL2_strawman_schedule.pdf

Minutes

- Reviewed minutes from previous meeting

- Sasha showed wiki page he started for FCAL2 installation

- gave 7 possible categories of condition of existing glass modules

- Lead glass modules have aluminum towards glass

- Crystals have mylar towards crystal

- Sasha estimates 40 minutes to rewrap a module with proper training

- Need to determin qty or al mylar, silicone sheet and what else needs to be procured

- Suggested students can do wrapping

- Showed HV and current for each existing module

- maybe 2 people from Cuevas to help with unstacking and stacking

- Tech group will have availability during this time

- Detector support group may have folks available to help

- Sasha needs more time for cable mapping - will make separate meeting

- Mark Dalton presented status of existing modules in 4 categories

- 187 original bases saturated

- 206 new bases saturated

- 1018 new bases < 1790V

- 1309 original bases < 1790V

- Possibility to mark prior to removal

- Maybe perform stress test on existing modules to see condition prior to removal

- Maybe remove bad bases before unstacking - need to plug end so pmt does not fall out

- Have about 50 good spare pmts besides 400 that will not be used

- discussed pre-sorting as removing from stack vs. just toss them in a bin for sort later

- Need to work out sorting procedure to determine required shelving

- do we also wish to inspect from US side prior to unstacking to label cracked or brown ones?

- Chris S. ordered 1600 RG174 signal cables and connectors - 20 weeks - $83K

- Have all external HV cables on connectors - they still need to be attached

- Lengths are needed for all HV and LV cables inside dark room

- LV cables are ribbon cables inside dark room

- No daisy chaining

- Can we reduce to 3 wire instead of 10 to save space?

- Monitoring Panel

- fibers have about a 1" bending radius with 10% loss in signal

- Leave clearance on side edges of Rohacell to allow fibers to come out and bend around US surface of outer monitoring panel

- Outer plexiglass and rohacell can be held together using plastic push pins

- Need to get details from Matt S. for outer LED attachments

- discussed need for gasket on from brass face of each crystal to reduce possibility of cross talk

- Sasha discussed changing to individual fibers for each crystal

- is this needed for calibration?

- what is the requirement for the monitoring system?

- continue with the current design

- Final decision needed by December

- Arshak doing more studies

- Cable trays to be determined once cable configuration is defined

Action Items

- Set up separate meeting for Cable mapping and requirements - Tim

- Continue to work on unstacking, categorizing and repair plan - Sasha, Mark D.?

- Develop layout for patch panels - Stephanie/Chris S

- Continue to develop current monitoring design - Stephanie/Arshak

- Work on cable tray layout - Tim/Stephanie

- Provide lengths for HV and LV cables inside dark room - Tim/Stephanie